We Can Repair Your Concrete in Three Easy Steps

|

|

|

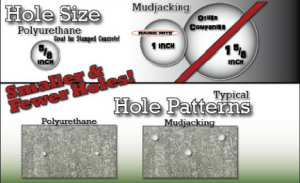

| Step 1 – Drill small 5/8″ holes in the existing concrete | Step 2 – Inject Polyurathane Foam filling the void and lifing the concrete | Step 3 – Patch the small holes making for a nearly invisible repair |

Our Product

- The polyurethane material is guaranteed for 10 years against any significant deterioration.

- The polyurethane material is unaffected by freeze-thaw cycles.

The material is extremely lightweight. By comparison, one cubic yard of “soil” weighs about 3,500 lbs; one cubic yard of low-mobility grout (mud-jacking) weighs about 3,000 lbs; one cubic yard of polymer material weighs about 250lbs! When using polyurethane, you are adding little additional overburden weight to an already distressed sub-grade.

The material is extremely lightweight. By comparison, one cubic yard of “soil” weighs about 3,500 lbs; one cubic yard of low-mobility grout (mud-jacking) weighs about 3,000 lbs; one cubic yard of polymer material weighs about 250lbs! When using polyurethane, you are adding little additional overburden weight to an already distressed sub-grade.- The material is inert to mildew and fungi, it does not get moldy or decay, nor does it nourish insects or rodents.

- The polyurethane material is completely waterproof and almost completely impermeable to other liquids, offering a strong, water-tight containment system.

- It is an eco-friendly solution that reduces the amount of concrete in landfills.

Our Process

- Concrete raising is an extremely clean process (no demolition or disposal).

Small 5/8″ diameter holes are drilled into the cement. Polyurethane foam is fed by hose through the cement, thus filling the void below and lifting the slab to its original position.

Small 5/8″ diameter holes are drilled into the cement. Polyurethane foam is fed by hose through the cement, thus filling the void below and lifting the slab to its original position.- It is much less intrusive than pouring concrete (no downtime). Since polyurethane cures sufficiently within minutes, you can use the treated area immediately, thus minimizing the disruption to your business and/or traffic.

- The small diameter of the drilled holes prevents slab-bottom breakout, and produces nearly invisible scarring on the concrete surface.

- Concrete raising costs 50% to 90% less than the traditional method of demolishing, disposing, and re-pouring cement.